Supply

Conveyor belt

Skylift 400 is the Rosselli conveyor belt for loading large-sized timber . The usefulness of the width of 400 is to be able to load logs with a width greater than 40 cm or to have a larger transport channel. The galvanized sheet metal structure characterizes it to be able to move not only timber but also agricultural material . From processing waste, to vegetables and fruit.

Many of our customers have used it to move olives during harvest and when moving them to the mill. Making them clean and intact.

For height adjustment we have installed a rack system to be able to choose the height of use with greater precision and robustness.

It comes standard with a drawbar eye attachment and two pneumatic wheels to move it and move it to the place of work and use. In the process of moving it, through a second rack, I can retract the tubular structure so that it can be moved with less bulk or parked in the shed.

Technical table

|

Model

|

Tape width

|

Tape length

|

Tilting height MIN

|

Tilting height MAX

|

Supply

|

Dimension

|

Weight

|

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

Skylift 400 ID

|

400 mm

|

5500 mm

|

2400 mm

|

3500 mm

|

Tractor hydraulic circuit

|

1550x2100x2300 mm

|

275 Kg

|

|

Skylift 400 M

|

400 mm

|

5500 mm

|

2400 mm

|

3500 mm

|

Single-phase electric motor 220V - 0.75 kW 1 HP

|

1550x2100x2300 mm

|

290 Kg

|

|

Skylift 400 T

|

400 mm

|

5500 mm

|

2400 mm

|

3500 mm

|

Three-phase electric motor 380V - 0.75 kW 1 HP

|

1550x2100x2300 mm

|

290 Kg

|

|

Skylift 400 MSC

|

400 mm

|

5500 mm

|

2400 mm

|

3500 mm

|

Engine

|

1550x2100x2300 mm

|

300 Kg

|

IMAGES

These are the photos of our Skylify 400 conveyor belt

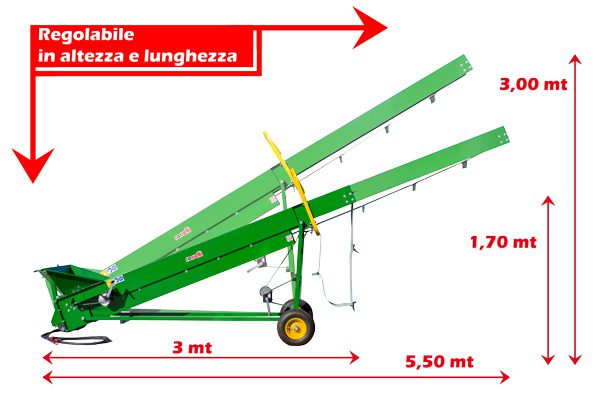

Possibility to adjust the belt in height and length.

The Skilift 400 is designed to offer maximum flexibility and ease of use. Thanks to a simple lateral crank, it is possible to adjust the inclination of the conveyor belt. This allows you to adapt the length and height of the belt to your specific needs. The adjustment system uses a robust rack, which guarantees the stability of the structure and allows you to change the positioning adjustment optimally without the risk of collapse.

In addition, the side walls of the Skilift 400 are telescopic and can be retracted. This feature reduces the overall footprint, making transport and storage of equipment extremely simple and fast.

When moving, it is easy to reduce the footprint of the Skylift 400 conveyor belt, making it easier to move with a tractor or other means.

Furthermore, the head wheel allows lateral translations, further facilitating movement.

Furthermore, when not in use, the Skilift 400 can be easily dismantled and stored, reducing the space required for storage to a minimum.

MODULAR PVC TAPE

The belt is made of high quality PVC modules, which allow the replacement of only the worn parts, thus reducing maintenance costs and times. It is equipped with a screw adjustment system. The modules are connected by metal paddles, allowing a quick and easy replacement of any module for a quick restart, without the need for interventions on the structure, also ensuring a long life.

Maintenance of the belt is simple and cost-effective. Thanks to the quality of the materials used, the PVC modules can be replaced individually when they show signs of wear, avoiding the need to replace the entire belt. This modular approach significantly reduces maintenance costs and minimizes machine downtime.

The tape is made of a nylon sheet coated with synthetic rubber (PVC), treated to ensure abrasion resistance and good resistance to temperature variations. This special treatment ensures that the tape maintains its mechanical and chemical properties even under difficult operating conditions, extending the life of the tape and reducing the need for maintenance.